Proqio delivers the mining industry’s most comprehensive data intelligence platform, unifying monitoring and operational data across your entire site. From pit wall stability and haul road integrity to tailings management and infrastructure health, Proqio transforms disparate data sources into a single, actionable view for enhanced safety, efficiency, and decision-making.

The Core Challenges in Mining Geotechnology & Operations

Modern mining operations face persistent challenges that require continuous, integrated insight:

- Geotechnical Risks: Slope stability in open pits, ground subsidence, and structural integrity of key infrastructure.

- Water & Waste Management: Balancing water security with the risks of tailings storage facilities (TSF) and containment.

- Operational Efficiency: Optimizing material movement, infrastructure maintenance, and project planning with live data.

- Compliance & ESG: Meeting stringent regulatory and Environmental, Social, and Governance (ESG) reporting requirements with verifiable data.

Proqio’s Unified Mining Platform: Connect Every Data Source

Eliminate data silos between departments and technologies. Proqio integrates and correlates all critical mining data streams.

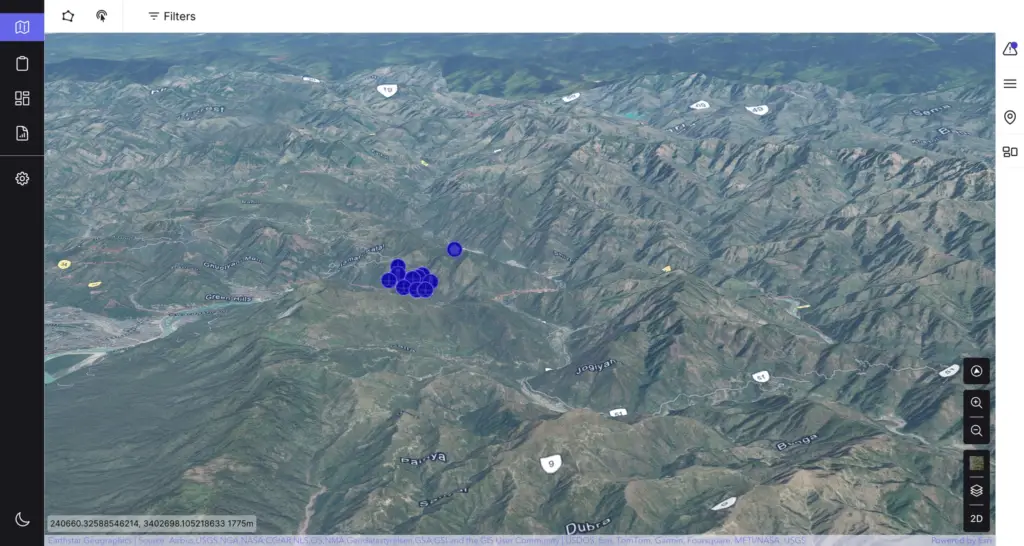

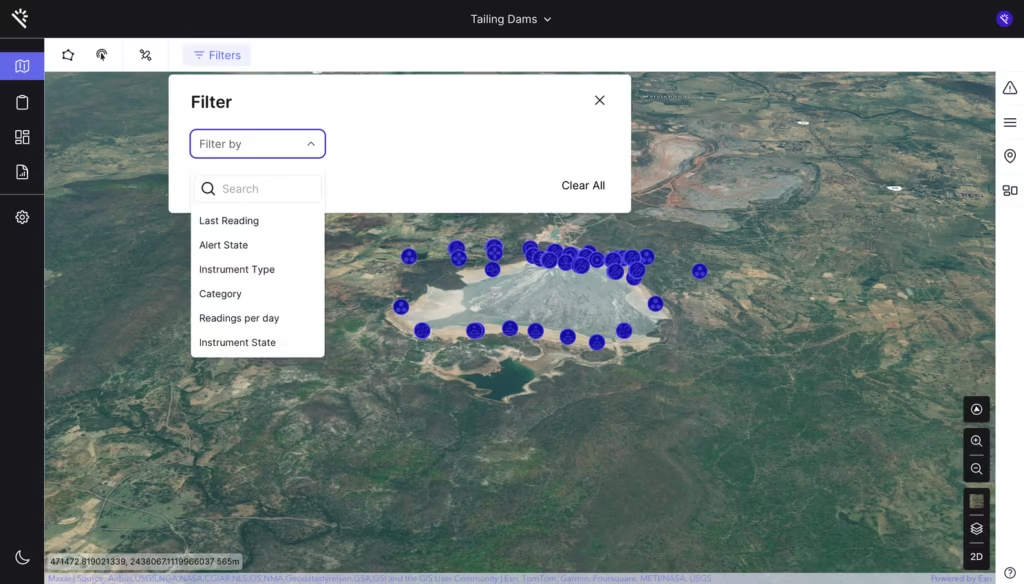

1. Site-Wide Geospatial Intelligence

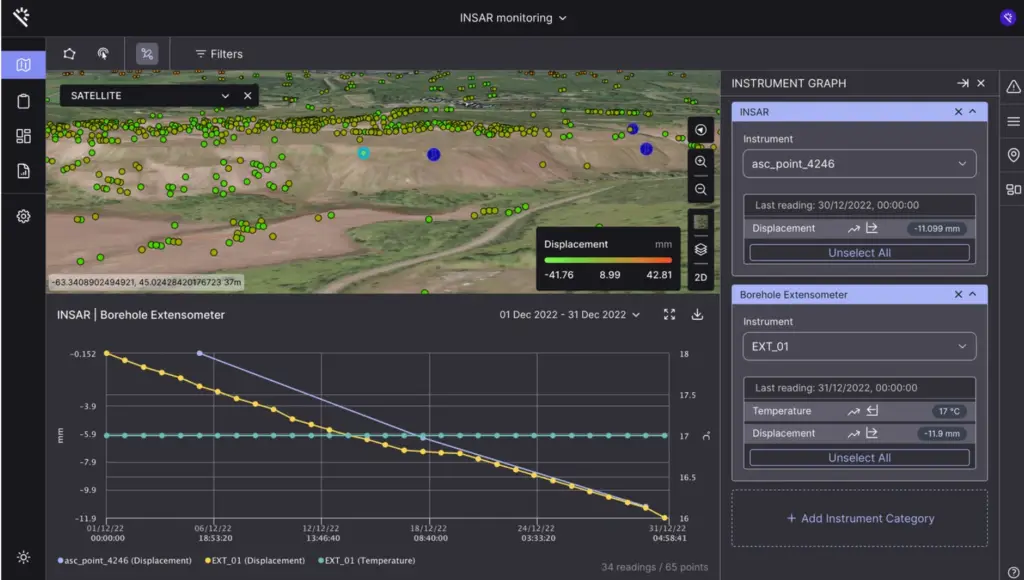

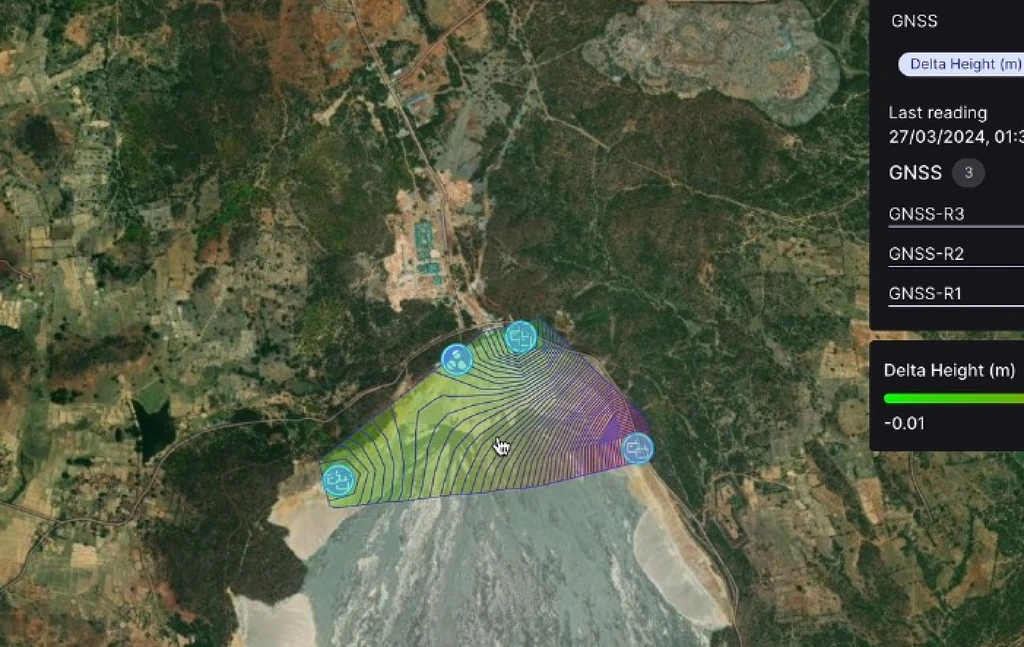

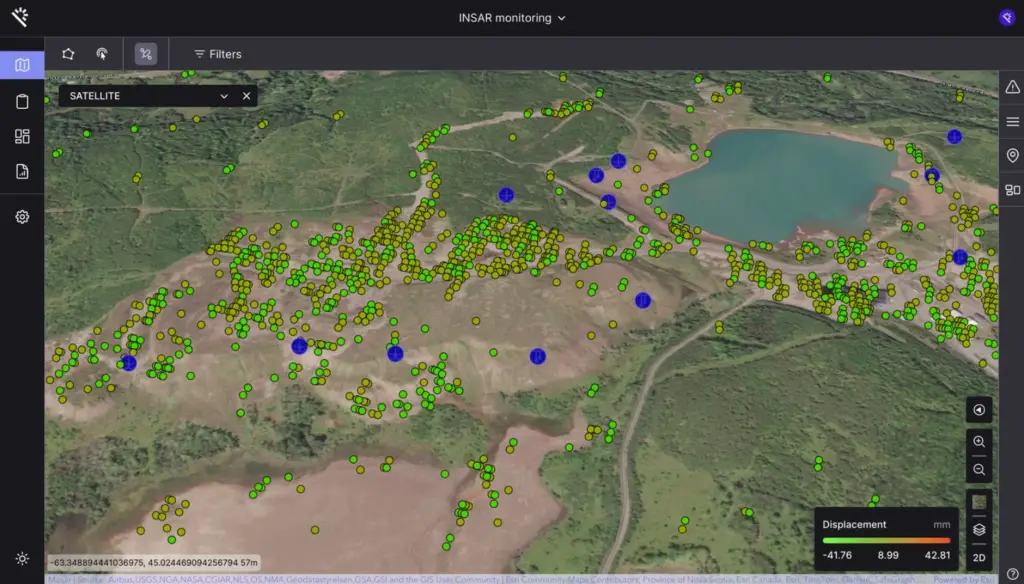

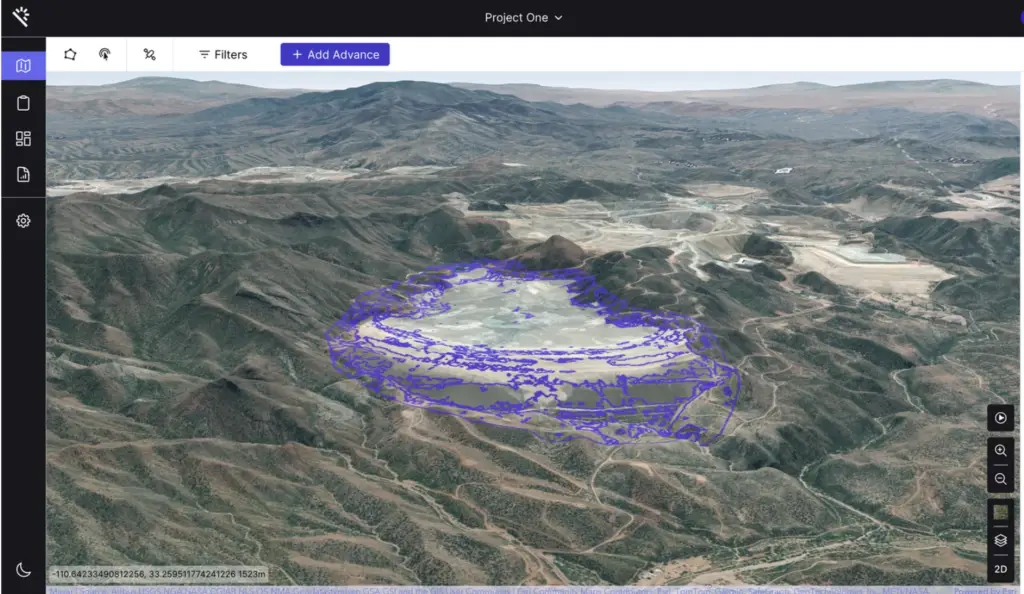

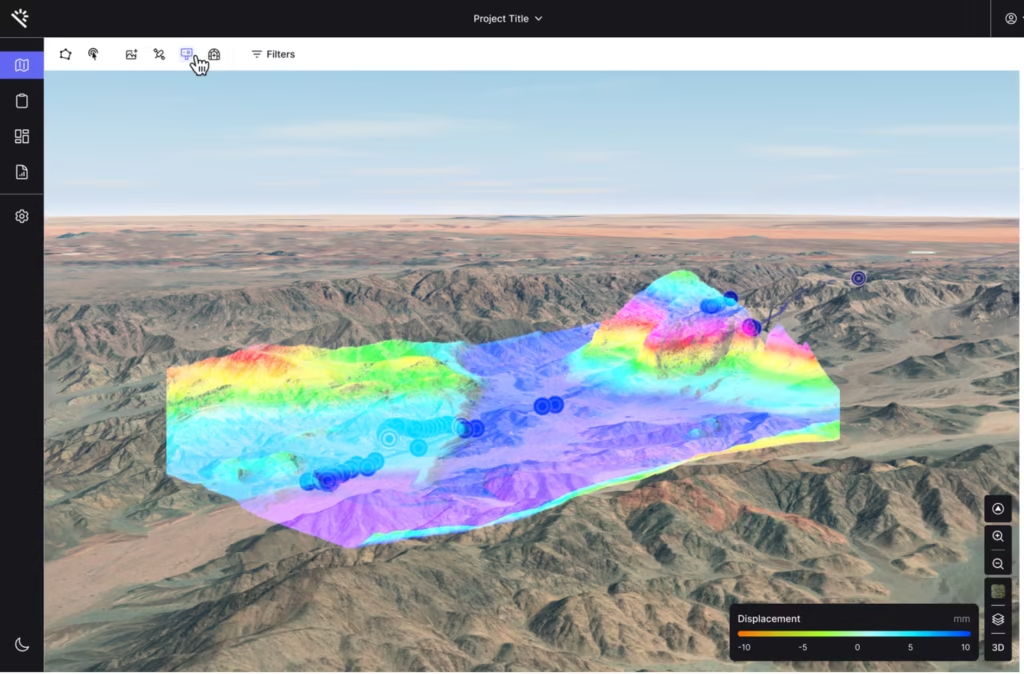

- GNSS-Calibrated InSAR: Monitor centimeter-scale ground deformation across the entire mining lease. Track pit wall creep, tailings dam movement, and regional subsidence with satellite precision.

- Drone & LiDAR Surveys: Generate high-resolution 3D topographies and volumetric calculations for stockpiles, pits, and waste dumps. Conduct rapid, repeatable surveys for progress monitoring and design compliance.

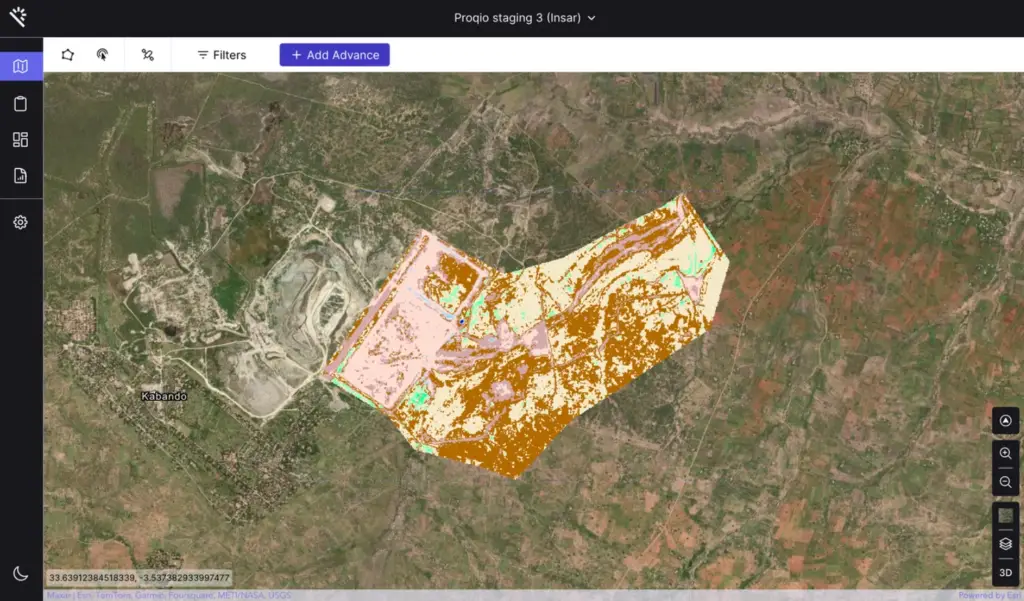

- Broad-Area Satellite Monitoring: Track land use changes, water body extents, and vegetation health for environmental management and closure planning.

2. Precision Geotechnical & Structural Monitoring

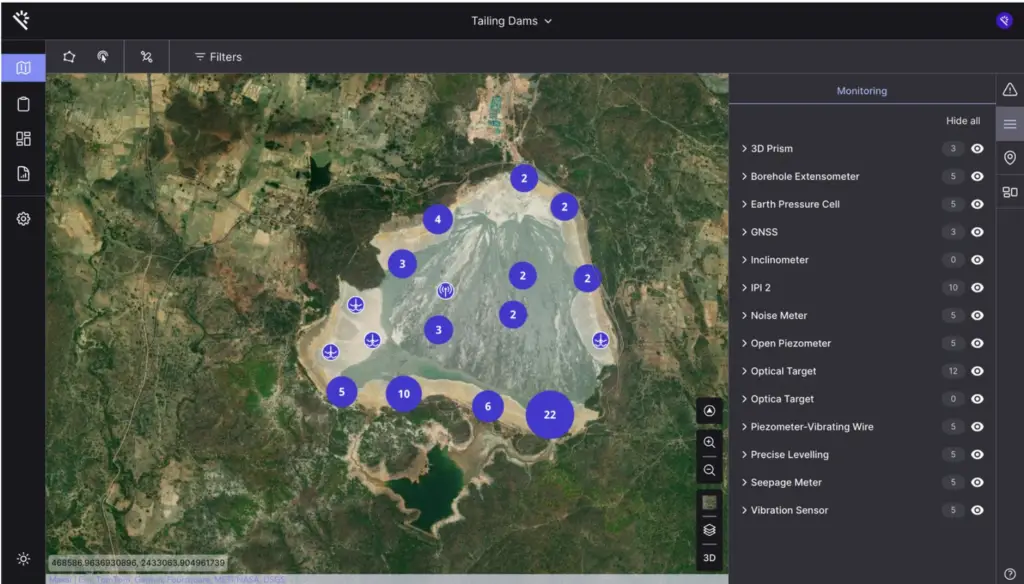

- High-Precision Sensor Networks: Integrate data from hundreds of geotechnical instruments—piezometers for pore pressure, inclinometers for subsurface shear, extensometers for crack movement, and vibrating wire sensors for stress.

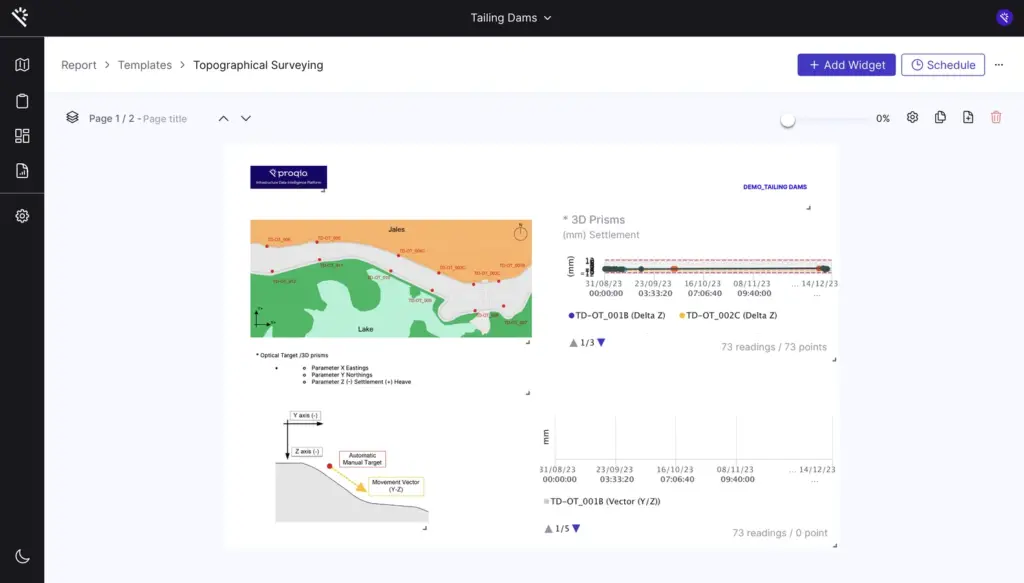

- Geodetic Monitoring Systems: Combine robotic total station and GNSS data for real-time, millimeter-accuracy displacement monitoring of critical points on highwalls, conveyors, and processing plants.

- IoT & Wireless Mesh Networks: Deploy robust, low-maintenance sensor grids across remote or challenging terrain for reliable data acquisition on dust, vibration, tilt, and environmental conditions.

3. Operational & Fleet Data Integration

- Go beyond traditional monitoring. Correlate geotechnical data with operational parameters for a complete picture.

- Fleet Management Data: Understand how heavy vehicle traffic impacts haul road stability and near-pit vibration.

- Processing Plant Sensors: Monitor foundation settlement and structural vibration of critical processing infrastructure.

- Blast Monitoring: Integrate seismograph data to assess vibration impact on slopes and nearby structures.

Advanced Analytics for Proactive Mining Management

Proqio provides the tools to move from reactive data review to predictive operational insight.

Dynamic Visualization & Cross-Correlation

- Unified Operational Dashboards: Create role-specific views for geotechnical engineers, mine planners, and operations managers, blending slope radar data with production schedules.

- GIS-Centric Analysis: Overlay InSAR deformation maps with drill hole data, planned pit phases, and infrastructure layers to identify spatial risks.

- Correlation Engine: Analyze relationships between variables—does increased precipitation correlate with rising pore water pressure in a specific slope? Does blasting vibration affect nearby sensor readings?

Predictive Insights & Automated Workflows

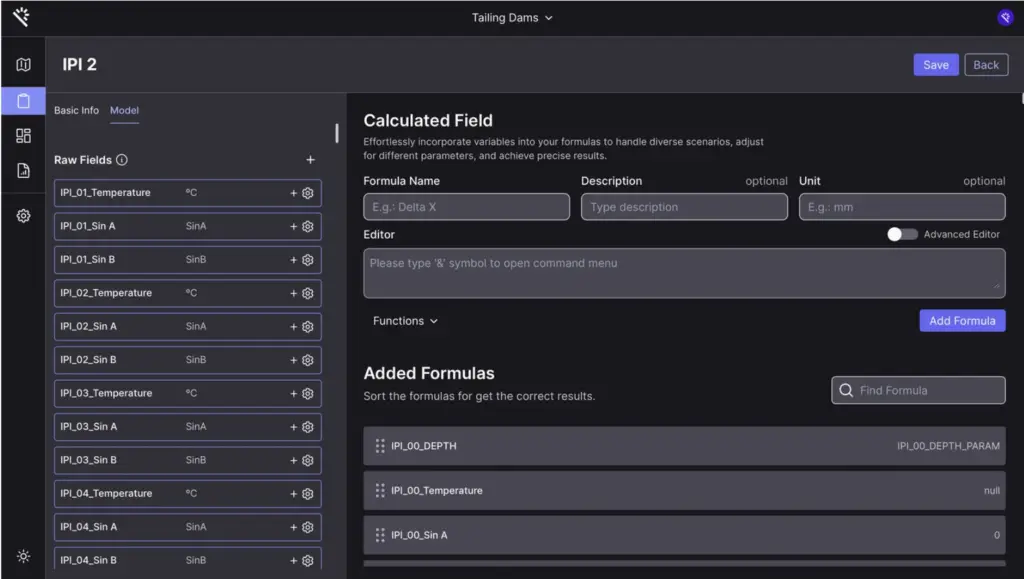

- Custom Data Models: Build site-specific calculation models for factor of safety, convergence rates, or water balance directly within the platform.

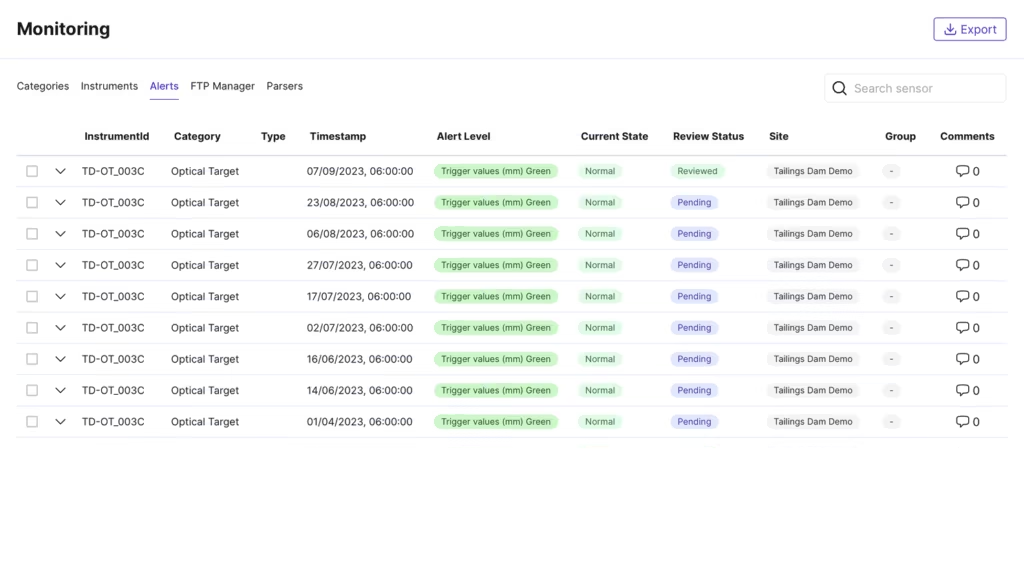

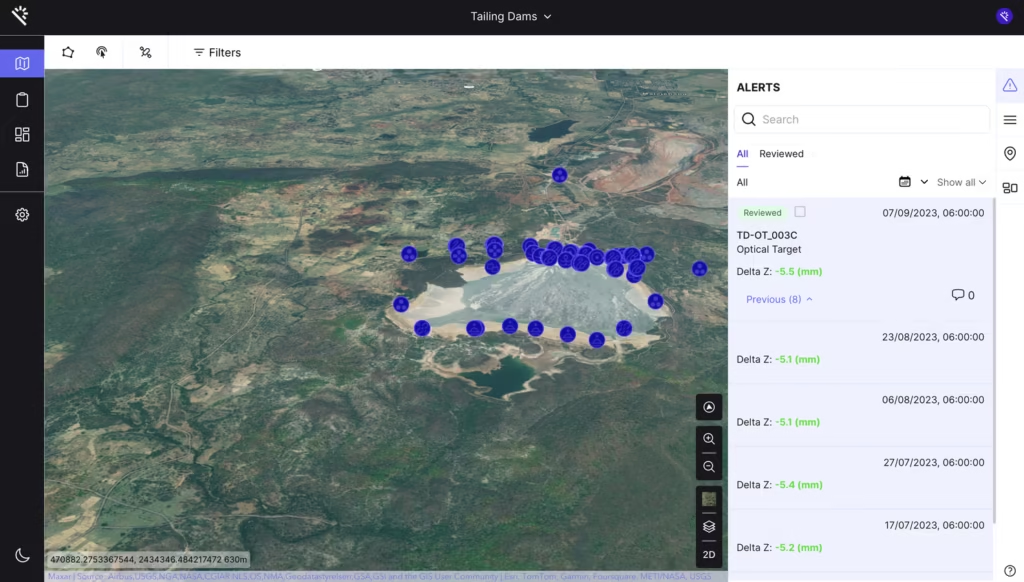

- Intelligent Alerting: Configure smart alarms that trigger based on complex conditions (e.g., “Alert if piezometer pressure rises by X AND it rains more than Y over 24 hours”).

- Automated Reporting: Generate daily stability reports, monthly ESG compliance summaries, and regulatory filings automatically, pulling live data from all connected systems.

Driving Safety, Efficiency, and ESG Performance

Proqio creates a collaborative data environment that enhances every aspect of mining.

- Risk-Informed Decision Making: Plan pit expansions, waste dump locations, and drilling programs with a clear understanding of real-time geotechnical constraints.

- Enhanced Operational Safety: Provide crews and engineers with access to live dashboards showing current hazard zones, slope stability ratings, and restricted areas.

- Streamlined Compliance & Audits: Maintain a single, immutable record of all monitoring data, reports, and actions. Simplify internal and external audits for safety and environmental regimes.

- Life-of-Mine Data Continuity: Securely archive and manage data from exploration through to operation and closure, building a valuable geo-data legacy for future modeling and liability management.

The Proqio Difference: Agnostic, Integrated, Intelligent

Unlike point solutions, Proqio is technology-agnostic, seamlessly connecting data from over 100+ sensor types, proprietary software, and operational systems. It is the central intelligence layer for the modern, data-driven mine.

Ready to unify your mining data and transform operational insight? Request a personalized demo to see Proqio’s capabilities for your specific mining challenges.